| |

|

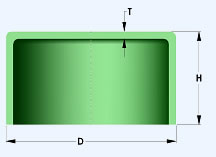

In general, the tonnage necessary to draw a shell of

round or rectangular shape is a function of the area of metal in the wall

(i.e. = mean perimeter and metal thickness). This is true because at any

given time, the force necessary to deform the metal equals the area of

metal being deformed multiplied by the yield strength of the material.

(In calculating these forces tensile strength is used, since this will

either draw the part, push out the bottom or tear the walls). This is

generally true for parts having odd shapes, although there are other factors

involved which complicate the operation.

|

|

|

| ROUND SHELLS |

|

TONNAGE =

Π x D x T x TENSILE STRENGTH/2000 |

|

|

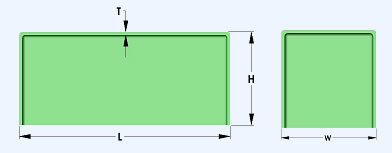

| RECTANGULAR SHELLS |

|

TONNAGE =

2 x (L+W) x T x TENSILE STRENGTH/2000

|

|

|

Mechanical punch presses are designed

to deliver their maximum tonnage near the bottom of the stroke. Since

drawing work actually starts before bottom, the full tonnage will not

be available. The above results, therefore, should be multiplied by "G"

factor when this type press is used. |

H |

"G" |

H |

"G" |

H |

"G" |

H |

"G" |

1/2 |

1 |

3 |

1.75 |

10 |

3 |

18 |

4 |

1 |

1 |

4 |

2 |

12 |

3.25 |

20 |

4.25 |

1 1/2 |

1.5 |

6 |

2.5 |

14 |

3.5 |

22 |

4.5 |

2 |

1.5 |

8 |

2.75 |

16 |

3.75 |

24 |

4.75 |

|

Ring Holding Pressure or Force

The primary function of the draw ring is to hold the blank while it is being

formed to prevent wrinkles. Since the resistance to wrinkling becomes greater

as the metal thickness increases, the necessary R.H.F. decreases. Experience

indicates that a close approximation to the R.H.P. can be obtained by multiplying

the tonnage required to draw the shell by "J" factor (Chart 2).

Note: Disregard "G" factor for this calculation. |

|

Press Tonnage

Size of press necessary to draw shell in question is as follows:

MINIMUM PRESS TONNAGE = SHELL TONNAGE PLUS CUSHION TONNAGE (RHP)

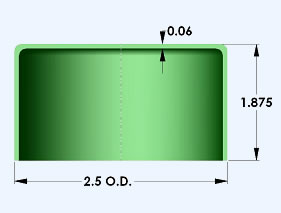

Example

Determine the size of mechanical press required to draw the shell pictured.

|

| DRAW TONNAGE = Π x (2.50 - 0.06) x 0.06

x 55,000 / 2000 = 12.7 T x 1.5 ("G") = 19.0 T |

| CUSHION TONNAGE =

12.7 x 0.133 ("J") = 1.7 T |

| MINIMUM MECHANICAL PRESS TONNAGE = 19.0 T

+ 1.7 T = 20.7 T |

| MINIMUM HYDRAULIC PRESS TONNAGE = 12.7 T

+ 1.7 T = 14.4 T |

|

Dayton

Die Cushions

Dayton

Die Cushions Dayton

Die Cushions

Dayton

Die Cushions